- info@eltech.in

- +91-96196 86917, +91-84509 80333

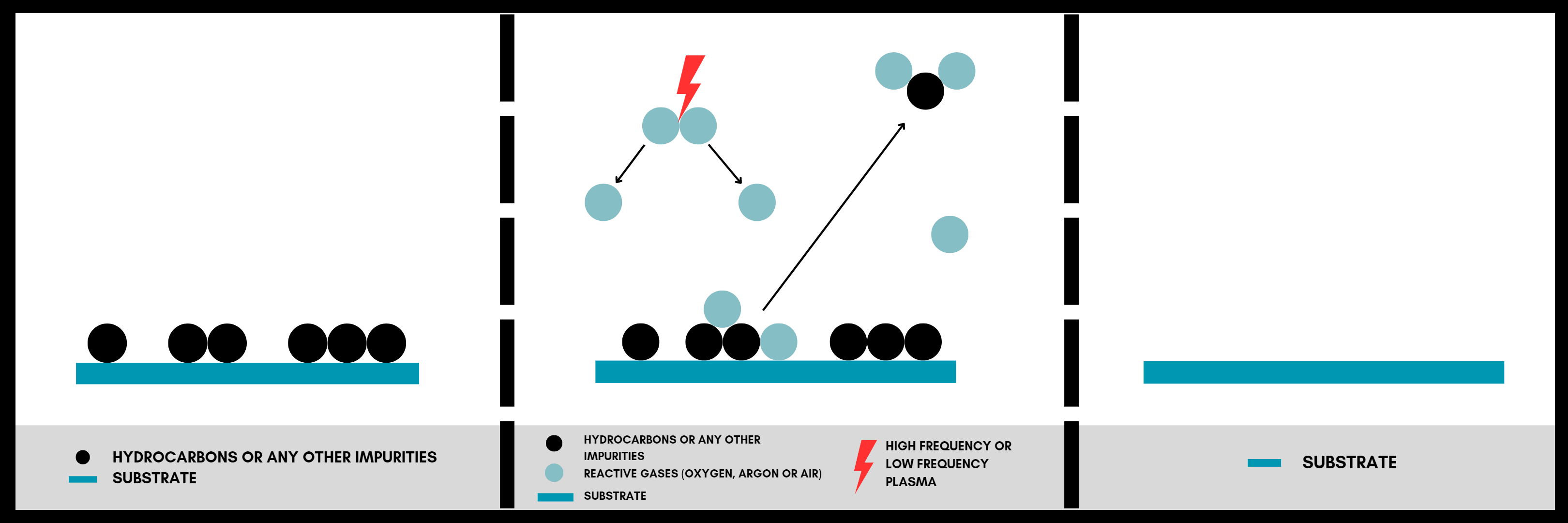

In Plasma Cleaning the hydrocarbons & contamination on the surface of the material is removed by the help of the ionised gasses. By chemical reaction or physical ablation of hydrocarbons on treated surfaces, plasma cleaning eliminates organic contaminants. Chemically reactive process gases interact with hydrocarbon monolayers to produce gaseous products, which are then removed by the plasma cleaner chamber's constant gas flow. Plasma cleaning can replace wet chemical techniques like piranha etching, which involve hazardous chemicals, raise the risk of reagent contamination, and expose treated surfaces to risk of etching. The gases which are generally used for cleaning application are Oxygen, Air or Argon. The plasma cleaning cycle is generally between 2-5 minutes depending upon the substrate and the application.

Plasma Cleaning is a "Dry" cleaning process and can replace environmentally damaging chemicals such as chlorinated hydrocarbons (trichloroethylene). Plasma is ideal for the surface cleaning of metal pressings/fabrications before bonding, sealing, painting and the removal of organic residues from surfaces prior to bonding, sealing, painting, soldering or wire bonding on a variety of metals e.g. gold, silver, titanium, copper or the removal of oxidation from plastics, rubbers and elastomers.

Some common terms associated with Plasma Cleaning are as follows: Vacuum Plasma Cleaning, Vacuum Plasma Cleaning, Plasma Cleaning