- info@eltech.in

- +91-84509 85885

Eltech Engineers is well known firm famous for manufacturing innovative industrial products i.e. static charger is one of them. This static charger is useful during injection molding process to stick poly propylene / polyester films / thin biaxial oriented poly propylene films / water resistance films / fire protection film / photo sun film / flex board film / crystalline films / polystyrene foil material to the inner mold surface. Special care has been taken while designing and manufacturing of such high class products to match with the international quality and considering industrial safety standards & of course as per customers' needs to satisfy them which are on the top priority. That's why Eltech Engineers is leading name in the same field of producing & supplying superior quality static charger at reasonable price to cope up with completive market environment. These machines are suitable for thin foil charging in injection molding and blow molding machine i.e. portable applications in domestic as well as industrial use.

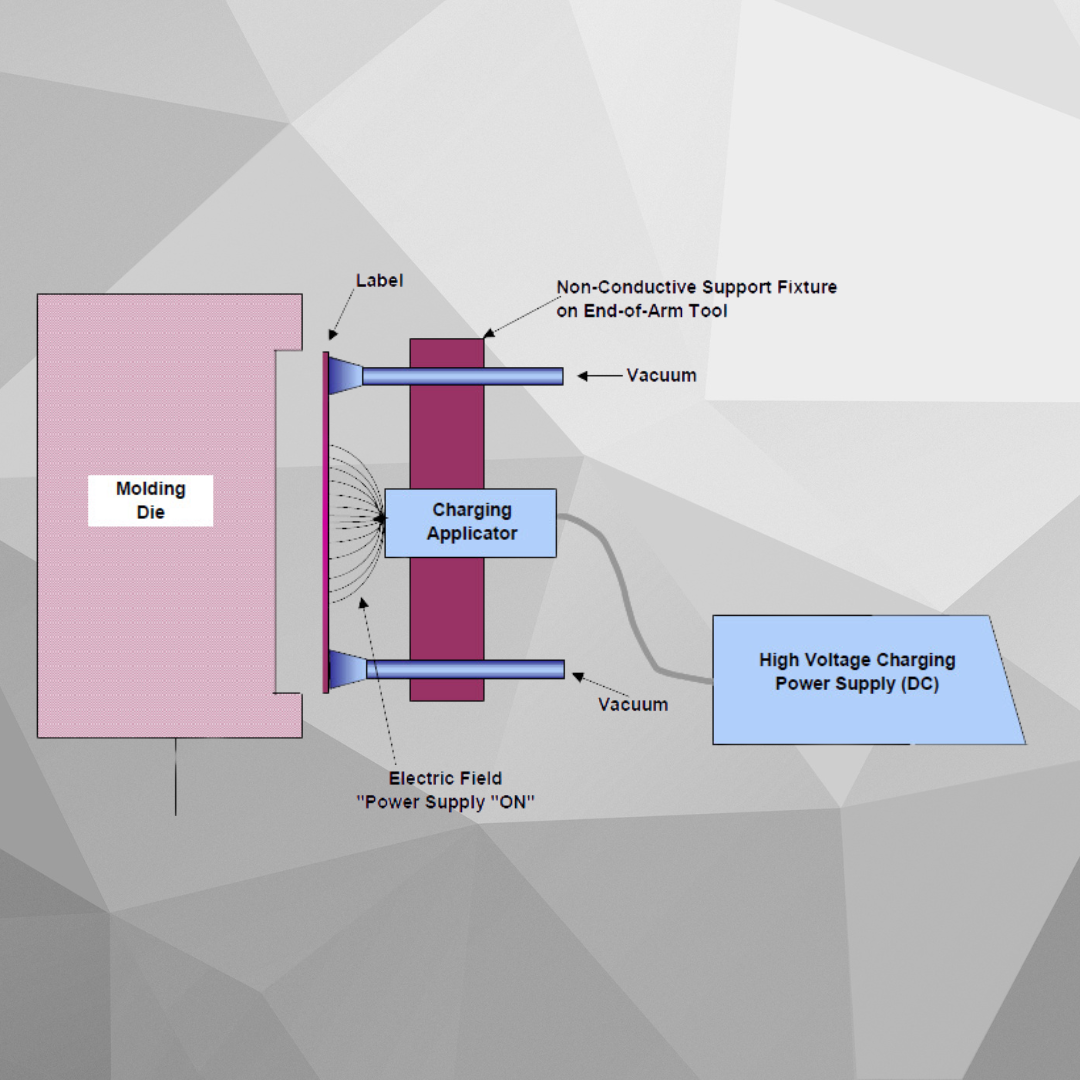

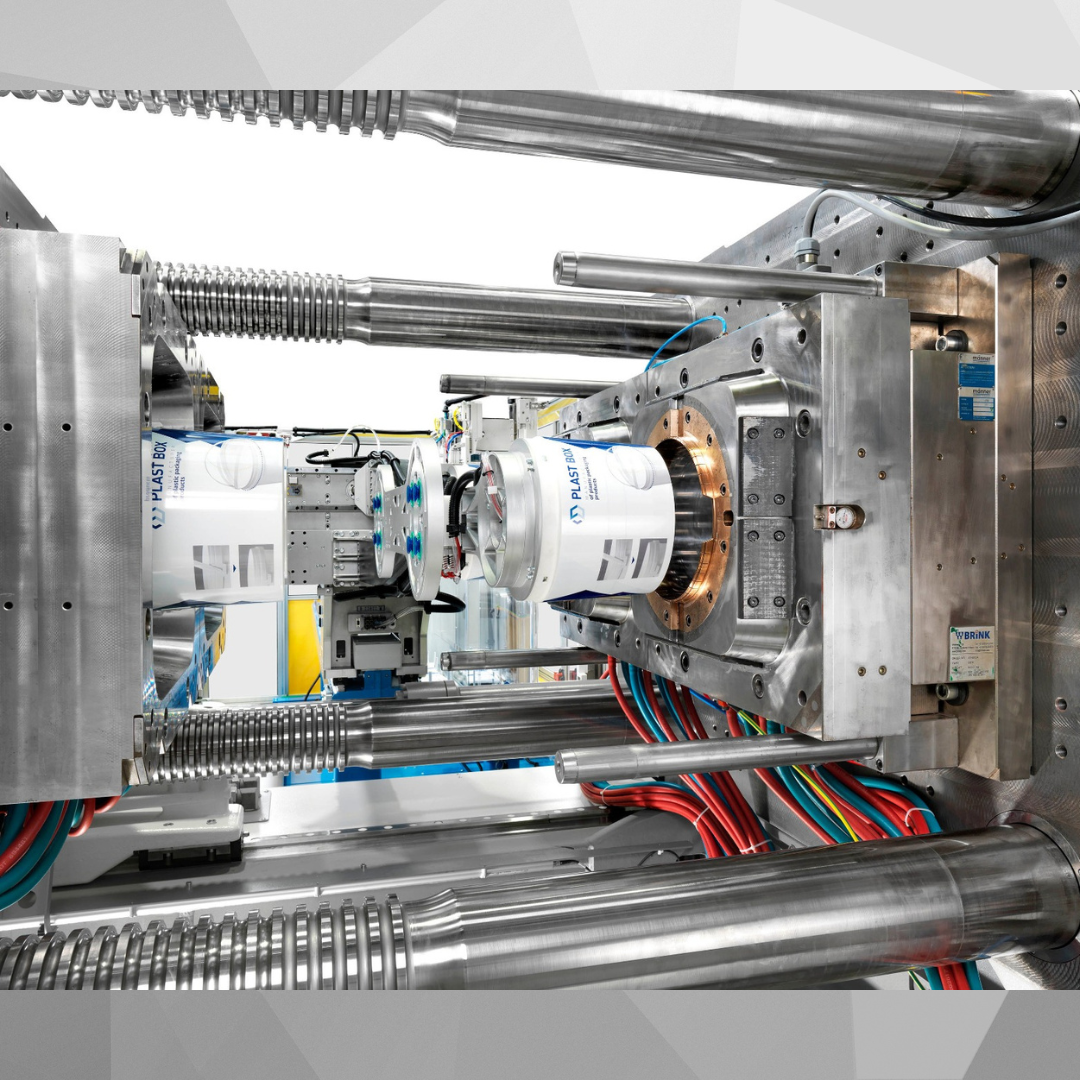

Applications In mould labelling (IML). Static charges can be used to pin a decorative label tight against the inner mould surface during injection moulding without the use of vacuum. This procedure greatly improves finished product quality. Outside the mould a robot presents the label to a charging bar which applies an electrostatic charge to the label. The label is then placed into the mould cavity, where it sticks due to the electrostatic bond between the label and the metal mould wall. The label will not slip or change position in the mould.

Whether you are an end-user or a robotics manufacturer, Eltech can assist you with advice and knowledge in creating the perfect In Mold Labeling solution. It is essential when starting a new IML project to make the right decisions to create a competitive product.

Outside the mould the robot picks-up a single, pre-printed label to transport (high-speed) and place it into the mould cavity (single or multiple), where it sticks due to the electrostatic bond between the label and the metal mould wall (ground potential). Therefore the label will not slip or change position in the mould during the moulding process and a perfect In Mould Labelling result can be achieved with an optimal cycle-time.