- info@eltech.in

- +91-84509 85885

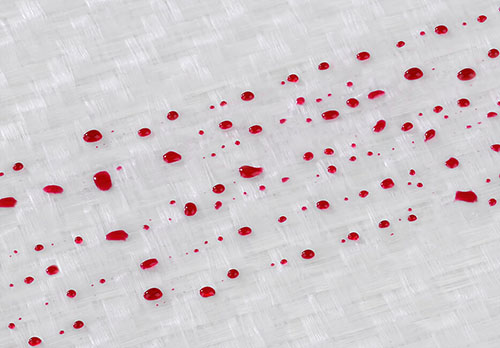

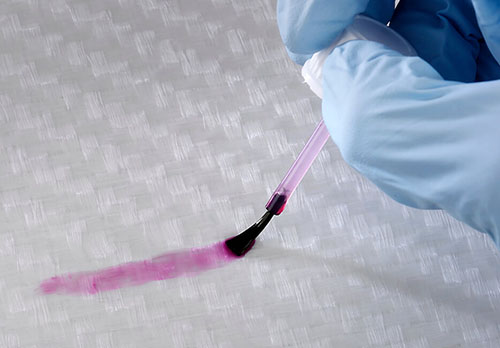

The Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks.Corona treatment system increases the surface tension of the fabrics respective to inks by inducing molecular changes in the surface of the films. This is done by exposing the air at the material's surface to a high-voltage electrical discharge - a corona. Corona discharge treatment at atmospheric pressure for improving adhesion of various polymer substrates is now standard practice.

In the presence of a high voltage discharge in an air gap, free electrons, which are always present in the air, accelerate and ionise the gas. When the electric discharge is very strong, collisions of high velocity electrons with molecules of gas result in no loss in momentum, and electron avalanching occurs. When a plastic part is placed in the discharge path, the electrons generated in the discharge impact the surface with energies 2 to 3 times that necessary to break the molecular bonds on the surface of most substrates. This creates very reactive free radicals. These free radicals in the presence of oxygen can react rapidly to form various chemical functional groups on the substrate surface. Functional groups resulting from this oxidation reaction are the most effective at increasing surface energy and enhancing chemical bonding to the resin matrix.Surface treatment with high voltage discharge modifies only the surface characteristics without affecting material bulk properties.

To be able to successfully bond, coat, print or paint polymers and metals, the surface must first meet a few requirements. It has to be very clean and has to be sufficiently active to form an adhesive bond with the coating material. Corona pre-treatment takes care of both of these requirements: The reactive corona species transform the finest organic layers to the gas phase during ultra-fine cleaning. And with polymers, the functional groups described above are bonded to the outermost molecular layer, the surface polarity increases and the prerequisite for adhesive bonding with the applied material is fulfilled.

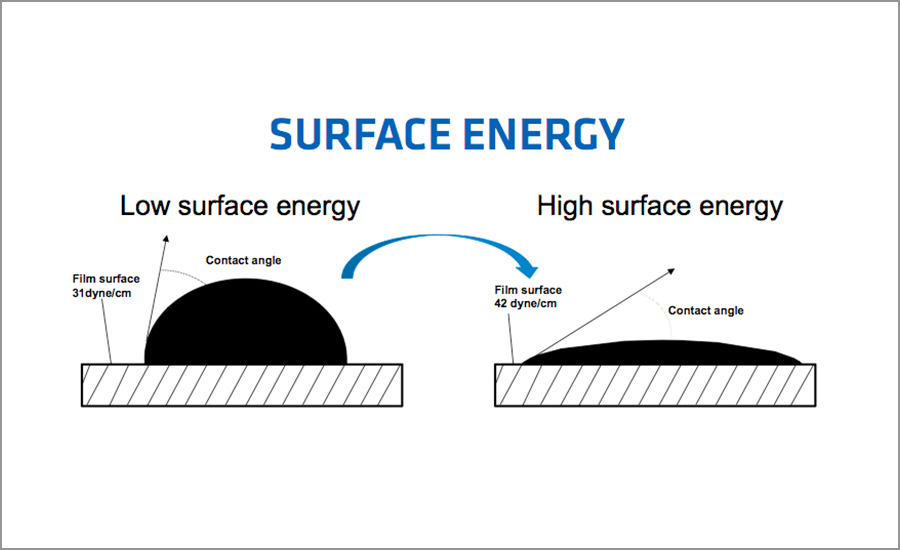

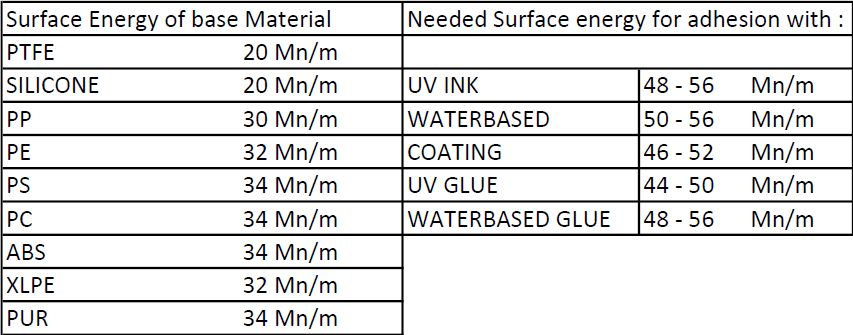

Figure shows absolute values of surface energy for solid materials and the surface tension of many plastics including polyethylene and polypropylene is often insufficient for bonding or printing. These materials have very useful properties such as chemical inertness, a low coefficient of friction, high wear, puncture and tear resistance, etc. However, the poor wettability of these polymers presents the designer with the problem of bonding or decorating these materials. Surface treatment can improve wettability of the material by raising the material�s surface energy and positively affect adhesive characteristics by creating bonding sites. The most advanced and successful methods of surface treatment are based on a principle of high voltage discharge in air.